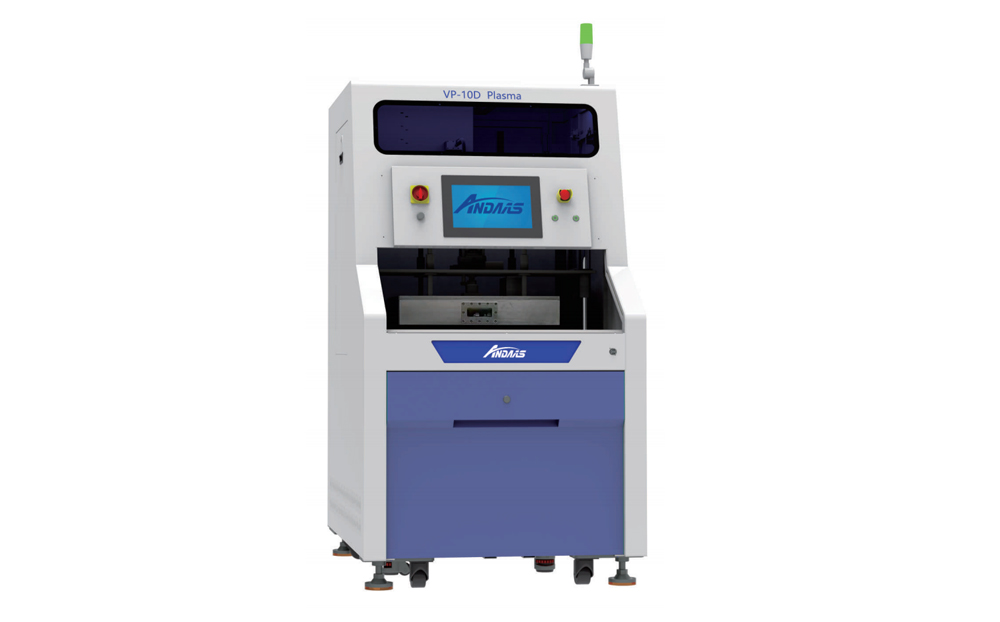

VP Series Plasma Cleaner

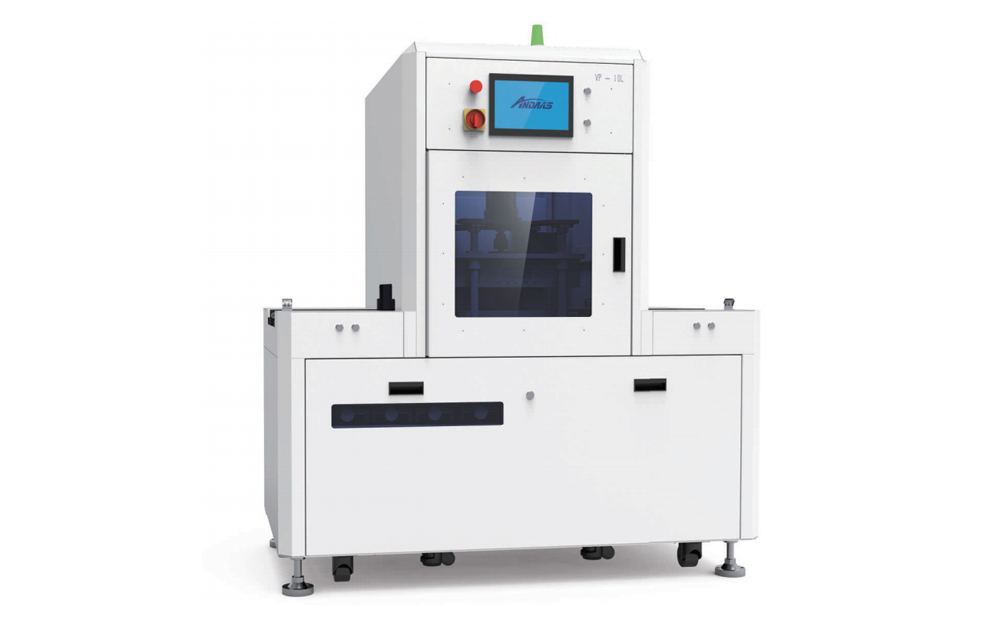

VP-10L Inline Vacuum Plasma Cleaner

Suitable for: Printing and packaging, mobile computer digital, plastic, glass, electronics, automobile, medical, metal, and other industries.

Typical applications: Remove dust and oil; fine cleaning and antistatic; improve surface adhesion; improve surface bonding reliability and durability

Advantages:

1> The conveying mechanism adopts electric amplitude modulation, and the width can be adjusted

2> Inline conveying system, which can communicate with the front and rear equipment

3>The vacuum chamber is made of aluminum alloy

4> Ultra-low temperature: the temperature is as low as 40 degrees

5> Omnidirectional surface cleaning: the anisotropic plasma can enter the ultra-fine slit for cleaning

6> Environmental protection: no harmful substances are produced before and after treatment, and it is far away from the harm of harmful solvents to the human body

7> Stability: Continuity and constancy to maintain the stability of machinery and equipment during operation

8> Cleaning: remove dust and oil, fine cleaning and antistatic

9> Activation: improve the adhesion of the surface, the surface energy of the object is greatly increased

10> De-plating: AF/AS layer is de-plating

| Functional configuration | Technical parameter | |

| Model | VP-10L | VP-10P |

| Dimensions | L=1600, W=1010, H=1750 (mm) | L=1600, W=1010, H=1750 (mm) |

| Weight | 540KG | |

| Control | PLC | |

| Vacuum time | 15S | |

| Applicable product size | Width≤350, Length≤370, Height≤18 (mm) | |

| Conveying height | 900±20mm | |

| Transmission direction | □Left→right (standard) □Right→left | |

| Conveyor drive | Stepper motor | |

| Power supply | Three-phase 380V | |

| Total power | 3.5KW | |

| Industrial Gases | Oxygen, Nitrogen, Argon | |

| Communication port | SMEMA connector | |

| Vacuum breaking time | ≤5S | |

| Delivery method | Belt transport + cylinder transport | |

| Air pressure | 0.4-0.6 Mpa | |

| Display | 10-inch touch screen | |

| RF power | 0-500W (adjustable within the range) | 0-1000W (adjustable within the range) |