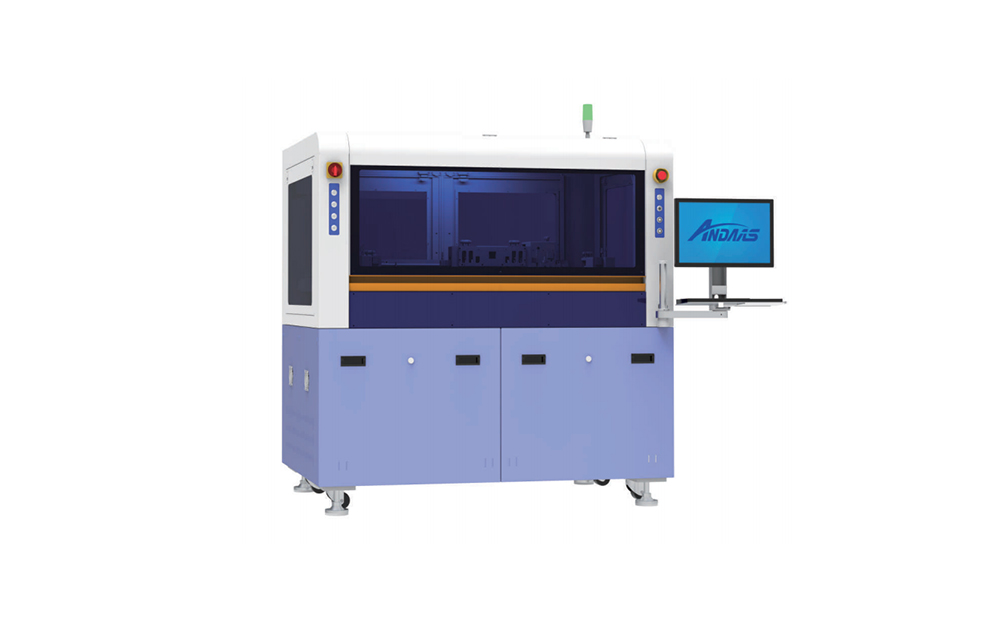

Handler (Test/burn/sorting)

Equipment introduction: With the rapid development of the semiconductor industry, chip testing and sorting machines have higher and higher requirements for equipment accuracy and speed. The turret testing and sorting machines use linear motors As the center, each station module runs in coordination, and completes all the testing and classification collection of the chip (swing disk, tape collection), mainly used in surface mount semiconductor devices The post-production process can complete the electrical parameter setting of the device, the classification selection and storage, the laser printing logo, the logo detection, the external dimension detection, and the packaging output.

Advantages:

1> Rotary type 16 stations are designed for high productivity (depending on test / burning time)

2> Optional module design (reel, tape, vibrating plate loading and unloading)

3> Small size of equipment

4> Can be equipped with various functions (AOI, laser marking, etc.)

| Functional configuration | Technical parameter |

| Dimensions | L=1600, W=1050, H=1640(mm) |

| Drive mode | Servo motor, stepper motor, DD motor |

| XY axis maximum moving speed | 800mm/s |

| XY stage repeatability accuracy | ±0.05mm |

| Z-axis repeatability | ±0.04mm |

| Pick and place method | Vacuum adsorption |

| Control System | IPC + bus |

| Test bit | 16 bit |

| Power supply | AC220V 50/60HZ |

| Air pressure | 0.4Mpa |

| Total power | 3KW |