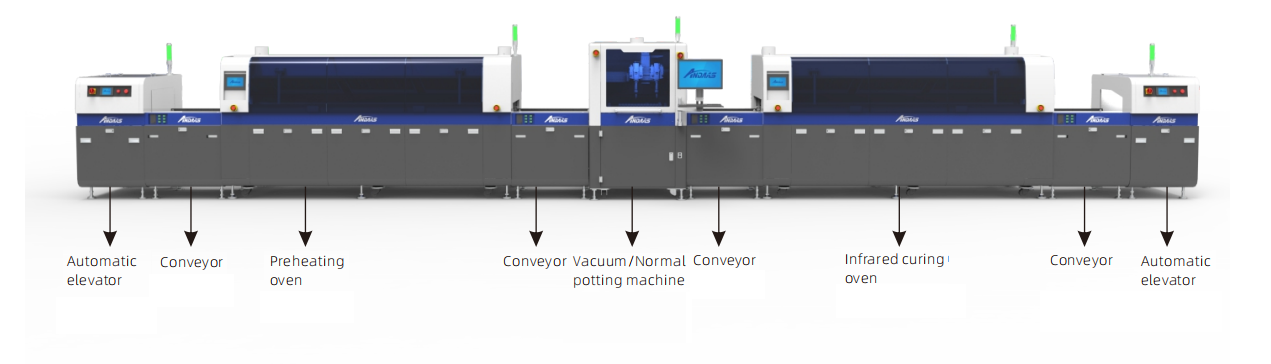

1. Intelligent potting production line, the line includes elevator, conveyor, preheating oven, visual photography, vacuum/normal pressure potting machine, curing oven, PC + PLC whole line control, humanized operation interface, fully intelligent production, providing customers with a complete set of automation solutions.

2.The equipment realizes the functions of automatic identification of product model, automatic potting, automatic drying, and automatic reflow of tooling.

3.The production line is pre-set with MES interface, which is easy to interface with the system and upload data covering production quantity, equipment anomalies, abnormal time, etc. The whole line is equipped with a variety of imaging systems, panoramic/3D camera to automatically identify the product potting position and automatically call out the potting procedure, automatic identification of the potting path and full-automatic potting, automatic drying of the product, automatic reflux of the workpiece without manual intervention, thus realizing the intelligent production.