SMTA International Conference and Expo 2024 was held in Rosemont, Illinois, USA from October 20-24, for what promises to be an unforgettable week of learning, networking, and fun. Whether you’re there to connect with industry peers, discover new solutions, or simply recharge your passion for the electronics manufacturing and assembly world, it was a right place.

SMTA International Expo is the heart of the SMTA events. This is where you’ll get hands-on with the latest products and services shaping the future of electronics manufacturing. It’s your chance to explore new technologies, discover solutions to the challenges you’re facing, and meet the innovators behind the breakthroughs. Whether you’re hunting for new tools to improve your processes or just curious about what’s on the horizon, the Expo is where inspiration strikes.

Anda Technologies, a leading provider of fluid application and custom automated manufacturing equipment, will showcase its latest innovations at booth during the 2024 SMTA International Expo in Chicago. The event was held October 22-24, 2024 at Donald E. Stephens Convention Center, Rosemont, Illinois, USA. Anda Technologies will be highlighting their large platform machines, emphasizing the capabilities of the iCoat-5L JetSelect Conformal Coating Machine, iJet-7 High Precision Dispensing Machines, the AP-3P Inline Atmospheric Plasma Treatment System, and the UV-2L Curing System featuring new UV light safety doors.

Anda Technologies Wins THREE Global Technology Awards for Dispensing, Plasma Treatment & Potting at SMTA International 2024

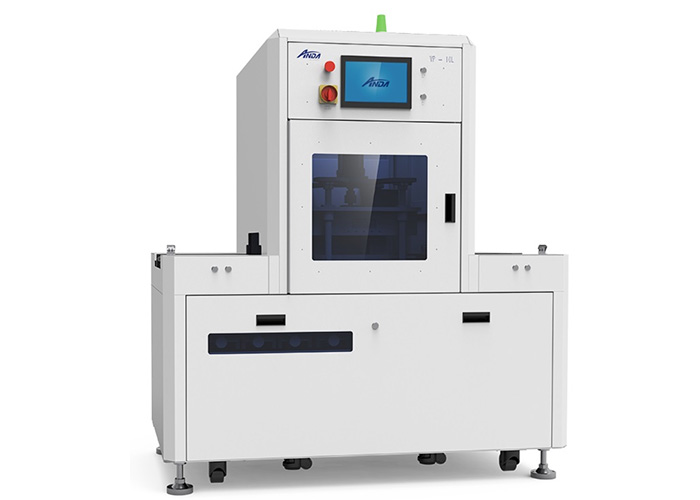

Anda Technologies have won three prestigious Global Technology Awards. The company’s innovative VP-10L In-line Vacuum Plasma Treatment System was recognized in the Plasma Treatment category, while the iPot-5 In-line Atmosphere Potting Machine received the award for Best Product – Asia, and the ADG-5DI 5-Axis Dispensing Machine was awarded in the Dispensing Equipment category. The awards were announced at an Oct. 22, 2024 ceremony during SMTA International.

Anda is honored to have our technologies recognized with these significant industry awards, all of these awards reflect our dedication to developing advanced solutions that enhance productivity, quality, and reliability for our customers worldwide.

The VP-10L In-line Vacuum Plasma Treatment System is a state-of-the-art solution designed to enhance surface preparation processes in various industries. This system uses advanced vacuum plasma technology to treat surfaces with high precision, ensuring optimal adhesion for subsequent processes like coating, bonding, or printing. The VP-10L features an in-line configuration, allowing seamless integration into existing production lines, thus enhancing overall efficiency and throughput. Its robust design and user-friendly interface make it suitable for both small- and large-scale operations, providing consistent and reliable performance.

This vacuum plasma treatment system is equipped with a range of customizable settings, enabling users to adjust parameters such as gas flow, pressure, and treatment time to meet specific application requirements. The VP-10L’s innovative design ensures uniform treatment across various substrates, including metals, plastics, and composites, improving the quality and durability of the finished products. Additionally, Anda Technologies has incorporated advanced safety features and real-time monitoring capabilities into the system, ensuring a safe, controlled operating environment.

The iPot-5 In-line Atmosphere Potting Machine is designed for precise, efficient potting applications in various industrial settings. This system handles the encapsulation of electronic components with high accuracy, protecting against environmental factors such as moisture, dust, and mechanical stress. The in-line configuration of the iPot-5 allows it to seamlessly integrate into existing production lines, optimizing workflow and increasing overall productivity. Its advanced dispensing system ensures consistent, uniform application of potting materials, enhancing the reliability and longevity of the encapsulated components.

Equipped with a user-friendly interface, the iPot-5 offers easy operation and customization, enabling operators to adjust dispensing speed, volume, and curing time to meet specific application requirements. The system supports numerous potting materials, including epoxies, silicones, and polyurethanes, making it versatile for different industrial needs. Additionally, the iPot-5 incorporates state-of-the-art safety features and real-time monitoring capabilities, ensuring a safe, controlled operating environment.

The Anda Technologies ADG-5DI Precision Fluid Dispensing System incorporates a cutting-edge linear motor gantry system that provides high-speed, precise motion control, ensuring accurate and consistent dispensing. Additionally, the ADG-5DI features advanced 3D inspection capabilities and laser height detection, which enhance its performance by enabling real-time adjustments and ensuring optimal dispensing quality.

The ADG-5DI significantly enhances speed and throughput in production lines with high-speed motors with linear speeds up to 1000 mm/s (39 in/s). Its multi-zone conveyor system allows for simultaneous processing of multiple products, reducing downtime and increasing efficiency.

Since 2005, the prestigious Global Technology Awards have recognized the absolute best new innovations in the printed circuit assembly and packaging industries. It brings together the global SMT and advanced packaging industry in a celebration of the companies and people that are achieving the highest standards and driving our industry forward.