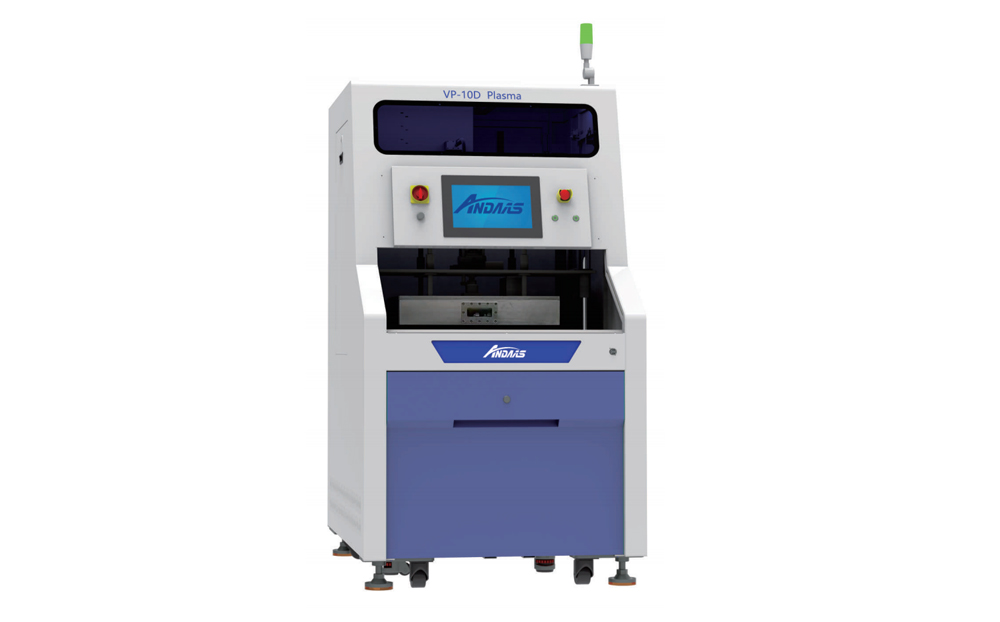

VP Series Plasma Cleaner

VP-10S Automatic Plasma Cleaner for Semiconductor

Designed for semiconductor packaging industry substrates and lead frames plasma cleaning process.

Typical applications:

1> Plasma treatment before wire bonding on semiconductor package substrates and lead frames

2> Plasma treatment before prefill on packaged chips

3> Pre-Mold Plasma Treatment of Semiconductor Package Substrates and Leads

4> Plasma treatment of semiconductor package substrates and lead frames to improve adhesion

5> Remove/reduce oxide layer on leads

| Functional configuration | Technical parameter | |

| Equipment size | L x W x H | L=1700, W=1200, H=1654 (mm) |

| Net weight | 1.0T | |

| Equipment perimeter clearance | 600MM on the back, 600MM on both sides | |

| Chamber | Volume | 9L |

| Channel | 4 | |

| Electrode number | 2pcs | |

| Load method | Magazine | |

| Adapt to product size | Width: 40-100mm, Length: 150-300mm | |

| Electrode | Electrode size | 528x300mm |

| RF generator | Standard power | 4KW |

| Frequency | 13.56MHz | |

| Gas control | Supports up to three channels | Standard 2 channels, optional 3 channels |

| Control system | HMI | PC + touch screen |

| Remote interface | Communication | Optional |

| Vacuum pump | Optional dry pump | 17CFM |

| Optional oil pump | 195CFM | |

| Optional dry pump with purge function | YES | |

| Nitrogen purge flow | 2SLM | |

| Evacuation time | 10-15S | |

| Vacuum breaking time | 3-4S | |

| Factory facilities | Power supply | AC380V 50/60HZ 4KW (Oil pump) / AC380V 50/60HZ 0.6KW(Dry pump) |

| Process Gas Line Size & Type | 1/4 inch Swagelok | |

| Process gas purity | Industrial grade and above | |

| Process gas pressure | 10-20psig | |

| Purge Gas Line Size & Type | 1/4inch Swagelok | |

| Purging gas purity | Industrial grade and above | |

| Purge gas pressure | 15psig | |

| Pneumatic Valve Line Size & Type | 10mm push-inftting | |

| Pneumatic gas purity | Compressed air, oil-free, dew point <=7C, particles <5 | |

| Pneumatic gas pressure | 70-90psig | |

| Compressed air exhaust line | 10mm | |

| Compliance | Certification | SEMI |

| Auxiliary equipment | Nitrogen generator (optional) | Optional when nitrogen purging function is required |

| Chiller (optional) | Optional when configuring the cooling function electrode | |

| Hydrogen Kit (Optional) | Optional when processing with hydrogen | |

| Exhaust gas processor (optional) | Tail gas treatment option for fluorine-containing gas treatment | |

| Transportation | Gross weight | 1.0T |

| Number of packages | 1 | |

| Packaging is SPM15 compliant | YES | |