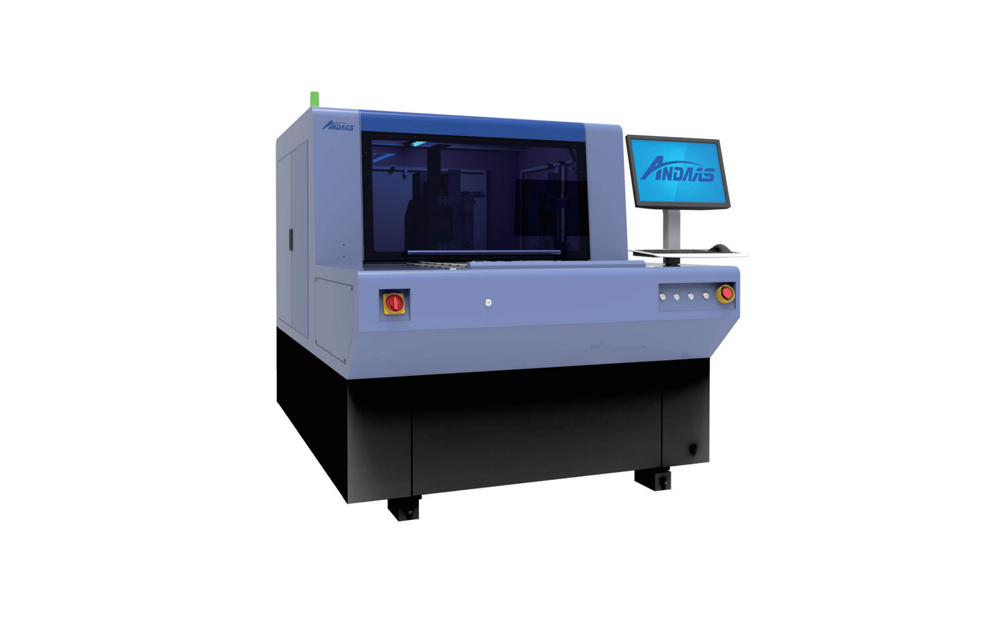

INKJET Printer Series

IP-150 Inline Inkjet Printer

Equipment Introduction: Provides ultimate protection for nozzle plate, longest maintenance-free production period. Provides stable print quality in terms of printing width used. For various applications such as tile decoration, labeling, direct forming, and other packaging printing, production of wood laminates, glass printing, and many other manufacturing processes.

Advantages:

1> High efficiency: Adopt linear motor drive & DD motor adjustment, XYU axis independent motion system.

2> High printing quality: Using advanced piezoelectric print head and variable ink drop printing technology, the minimum ink drop can reach 6PL, and the maximum ink drop can reach 42PL, with a variety of variable ink drop printing combinations.

3> High reliability: Equipped with an imported advanced circulating ink supply system, which can more effectively prevent nozzle blockage.

4> High stability: Equipped with an FFU positive pressure system, which can effectively improve the effect of inkjet printing.

| Functional configuration | Technical parameter |

| Device model | IP-150 |

| Effective ink jet area | L=200, W=140 (mm) |

| Ink supply system | Circulating ink supply |

| Printing accuracy | ±0.02mm |

| Resolution | 360dpi |

| Efficiency | 4S/PCS |

| Product height | 0.3-3 (mm) |

| Integral rack | L=1825, W=1045, H=1850 (mm) |

| Control method | Industrial computer |

| How to get in and out of products | Roller |

| Working height | 900mm±20mm |

| Input air pressure alarm | Menu + sound and light alarm |

| Air pressure | 0.6Mpa |

| Maximum operating speed | 1000mm/S |

| Input voltage | AC220V 50-60HZ |

| Power | 2KW |