With the rapid development of the times, technology and quality go hand in hand

In the wave of rapid development, China's economic outlook is changing with each passing day, from the era of "not having enough to eat", to the leap of "food and clothing", and then to today's well-off society, every step embodies the wisdom and sweat of countless Chinese. However, with the continuous progress of society, people's pursuit of quality of life is also improving, especially in the field of manufacturing, the requirements for product quality and scientific and technological content are getting higher and higher.

In the field of inkjet printing, traditional inkjet printing can only be printed on A4 or A3 paper, although a variety of non-standard printers have appeared later, but there are still pain points such as slow printing product speed, inaccurate printing position, need to customize non-standard platform, inconvenient to embed in the production line, and need manpower to maintain the printhead regularly. Starting from the customer's immediate pain points, Chubb Intelligent has independently innovated and developed the industry's first online continuous vision-guided inkjet printing solution, which completely solves the above pain points of customers.

Online continuous vision-guided inkjet printing redefines inkjet printing

Today, online continuous vision-guided inkjet printers have officially entered people's field of vision. It is not only a printing device, but also a new production tool that integrates high-tech and intelligence. Whether it is multiple products at the same time, or multiple types of products at the same time, the online continuous vision-guided printing system can easily complete the printing task when the product is transferred on the conveyor belt.

Imagine a busy production line where workers no longer have to spend a lot of time moving, loading, and unloading, all automatically by an online continuous vision-guided printing system. This not only greatly improves production efficiency, but also reduces labor costs, bringing tangible economic benefits to the enterprise.

Online real-time print quality inspection, one step ahead

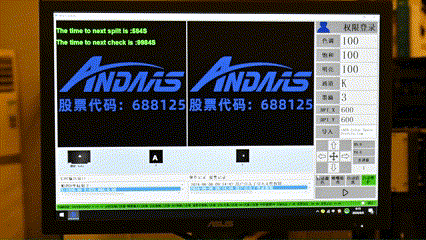

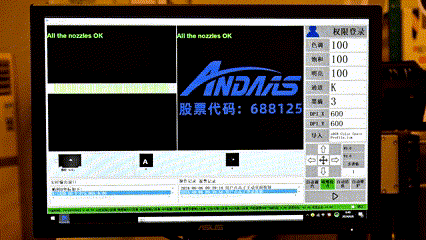

In today's well-off society, consumers are not only satisfied with the functionality of products, but also have higher and higher requirements for the quality of products. Chubb has an active insight into various market demands and is committed to providing customers with high-quality products. In the field of inkjet printing, we have launched a self-developed online real-time print quality inspection, which completes the print quality inspection in the instant after the product is printed, and can control the manipulator to remove the defective products to ensure that the products reach consumers and are 100% qualified for printing quality.

Intelligent sprinkler closed-loop maintenance, industry-leading technology

In the field of inkjet printing, the maintenance of printheads has always been a problem. The maintenance of the traditional inkjet printing equipment on the printhead is still in the backward technology of the relevant technical personnel's fixed-point inspection and maintenance, because the personnel are uncontrollable factors, often forget to maintain, etc., resulting in the plugging of the printhead and even scrapping, which has brought a lot of losses to the enterprise.

In-line continuous vision-guided inkjet printers will revolutionize that. It has carefully created an intelligent closed-loop maintenance function for the nozzle, using the method of visually judging the plugging condition of the nozzle and the automatic cleaning of the nozzle, so as to realize the regular monitoring of the plugging condition of the nozzle, and once the plugging hole is found, it will be automatically dealt with immediately. This intelligent closed-loop maintenance technology not only solves the drawbacks of manual maintenance, but also greatly improves the stability and service life of the equipment.

Efficient and stable, excellent quality

Because the online vision-guided inkjet printer does not need a complex mechanism positioning correction part, only a simple precision conveyor belt, and the product positioning completely relies on intelligent vision-guided soft correction, there is no equipment instability caused by aging and wear of the mechanism, or the deterioration of the accuracy of the printing position, etc., and avoids all kinds of scratches, scratches, and even scratches and other defects on the customer's products. The solution of visual position judgment soft correction avoids the gap of relative friction movement (at least 0.5mm or more) that needs to be reserved by the correction mechanism, and its highest accuracy can be achieved within 0.2mm, which greatly improves the position accuracy of product printing.

The wind is fast, and the efficiency is soaring

The principle of the traditional non-standard inkjet printing equipment is that the correction mechanism guides the product into a unified posture and passes through the bottom of the printhead one by one, and triggers the printing through the signal of the sensor, so it can only be printed one by one, and the efficiency is slow. Online vision-guided inkjet printers can locate multiple products at the same time, locate multiple products at the same time, and then print multiple products at one time, so the printing efficiency is greatly improved, and one device can top the production capacity of several traditional equipment.

One machine for multiple purposes, for the benefit of customers

Traditional non-standard inkjet printing equipment can only print a single product or part of the customer's products, and some irregular products cannot be printed accurately. The online vision-guided inkjet printing equipment does not need to move or rotate the product to correct the printing position, but only moves or rotates the printing data according to the visual positioning results, so it can print accurately no matter what product. It avoids the trouble and additional equipment costs that customers have to upgrade their equipment because of product upgrading.

Tailor-made to meet individual needs

In the manufacturing industry, each customer's needs are unique, so a tailor-made service is provided to the customer. Whether it is the specification of the product, the content of the print, or the layout of the production line, it can be customized according to the needs of customers to ensure that the equipment can be perfectly integrated into the customer's production process.