Embracing the era of Industry 4.0 and intelligent manufacturing, precision fluid control and surface treatment technologies have become core drivers upgrading the high-end equipment manufacturing sector. In response to increasingly complex production processes and the relentless pursuit of superior quality, Anda Automation remains at the forefront of technology, committed to providing customers with integrated automation solutions.

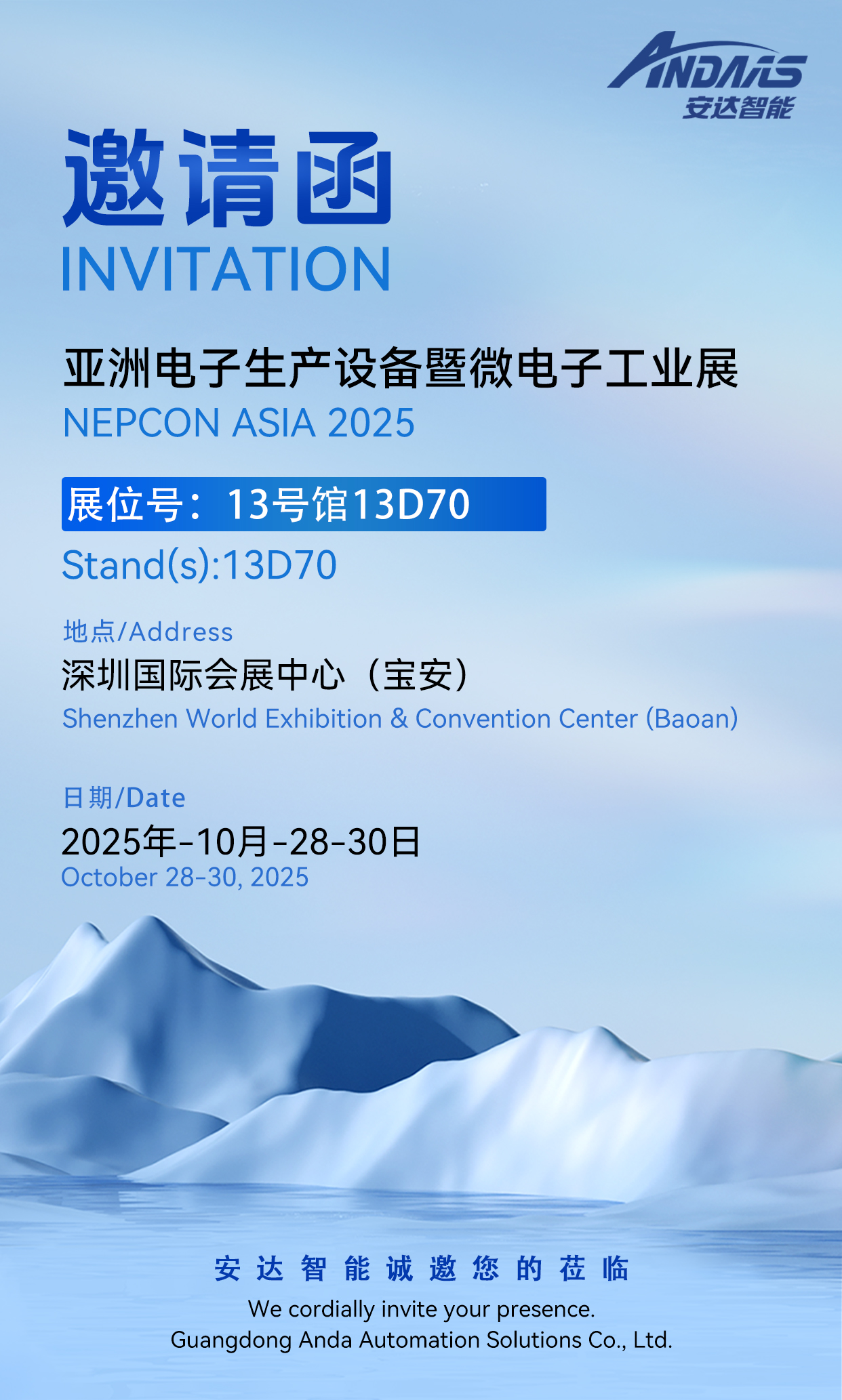

We are now honored to announce that we will be exhibiting multiple star products at NEPCON ASIA 2025, inviting you to explore new horizons in intelligent manufacturing together.

Today, industries such as consumer electronics, semiconductors, new energy vehicles, and medical devices are demanding more than ever from processes like dispensing, coating, cleaning, and potting. High precision, exceptional efficiency, superior consistency, and lower consumable costs have become the focal points of industry competition.

Manufacturing engineers now face critical, real-world questions: How can micrometer-level precision control be achieved? How can flawless coverage on complex 3D surfaces be ensured? And how can interfacial adhesion be enhanced to guarantee end-product reliability?

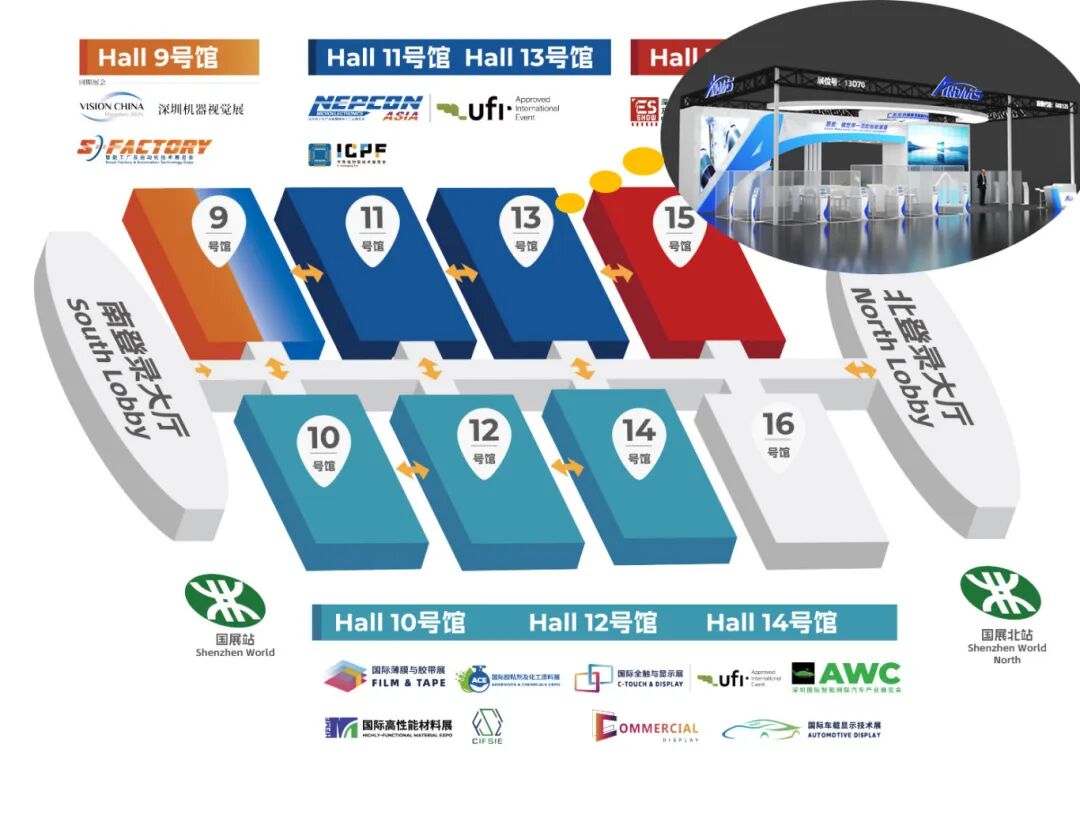

Event: NEPCON ASIA 2025

Date: October 28-30, 2025

Address: Shenzhen World Exhibition & Convention Center (Baoan)

Stand(s):13D70

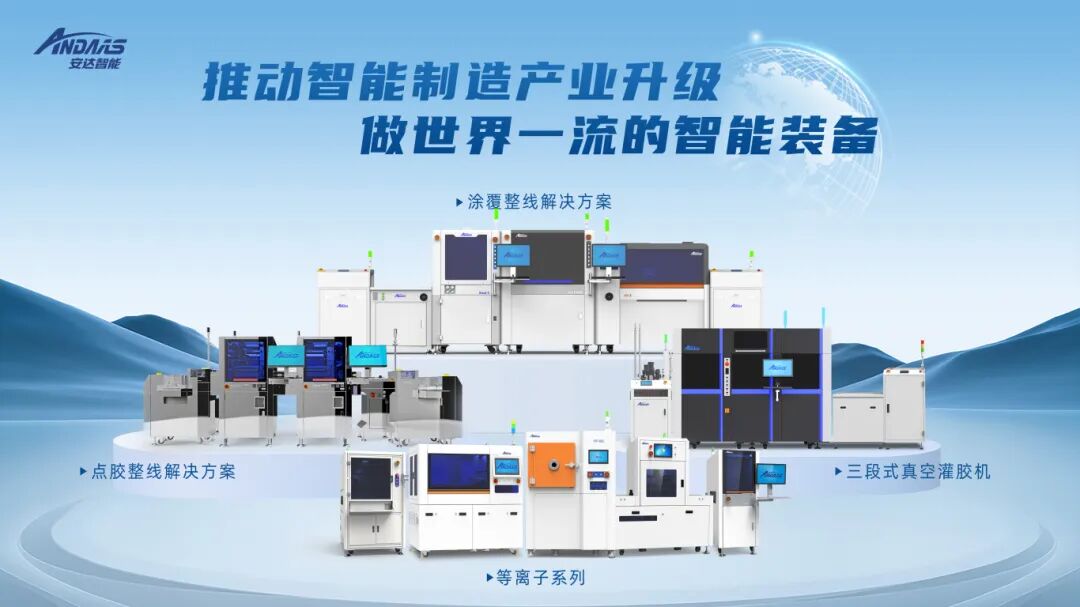

1、Core Products First Look: The Robust Power of an All-in-One Solution

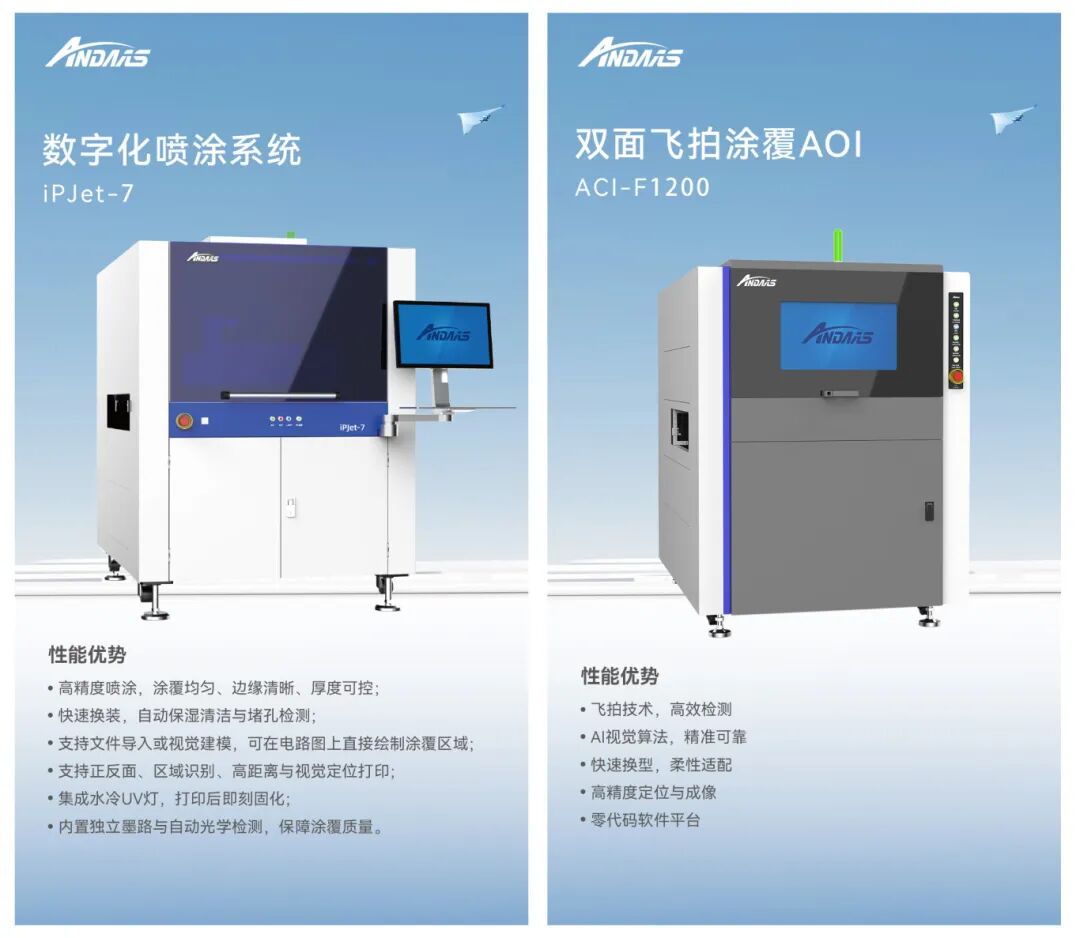

A New Product Premiere :Digital Coating System & AOI Inspection

Digital Spraying Solution: Integrating 3D printing, machine vision, and digital modeling technologies, this solution effortlessly handles complex three-dimensional workpiece surfaces. It ensures uniform coating distribution and reduces material consumption, setting the standard for future intelligent production. The innovative adoption of adhesive jet 3D printing enables instant curing after deposition, building 3D structures through multi-layer stacking. This eliminates the need for auxiliary processes such as masking or custom fixtures.

New-Generation AOI System: Making its debut, this system combines high-resolution optical lenses with deep learning algorithms to achieve fully automated, high-precision, and comprehensive quality assessment of coating results. By fundamentally replacing inefficient manual inspections, it ensures zero-defect product quality.

2、Proven Precision Process Modules

High-Precision Dispensing System & Fully Automatic Coating Machine

Dispensing System: Engineered for micro-volume, high-speed applications in chip packaging and mobile device assembly. Precisely addresses sealing, bonding, and thermal management challenges.

Coating Machine: Delivers uniform and efficient application of conformal coating and UV adhesives on PCBs, significantly enhancing product resistance to moisture, corrosion, and environmental contaminants.

Plasma Cleaning System

Two-Component Automatic Potting System

Designed for high-volume potting requirements in new energy battery packs and power modules. Ensures precise vacuum degassing and ratio mixing to guarantee product stability and safety.

3、核心技术解析

High-Performance Industrial Lenses & Precision Valves: A Disassembled Display of Core Components

We will present a disassembled display of the essential "senses" and "actuators" of our equipment, providing you with an in-depth look at the foundation of our exceptional performance. This offers professional insights for your equipment selection and maintenance needs.

To provide you with the most direct and in-depth understanding, we have meticulously designed an interactive booth experience. You will have the opportunity to engage in one-on-one discussions with our team of senior application engineers to address your specific process challenges. You can also witness all exhibited equipment in dynamic operation, experiencing its stable and highly efficient performance firsthand. We particularly welcome you to bring your product samples to the booth for complimentary trial processing and solution evaluation—letting the results speak for themselves and helping you embark on a new chapter in intelligent manufacturing.

Intelligence, flexibility, and sustainability are irreversible trends in manufacturing. Enhancing the performance of individual equipment is no longer sufficient to form a core competitive advantage. The key to future success lies in providing integrated, "turnkey" solutions that incorporate pre-treatment, precision processing, in-process monitoring, and data analytics. This is precisely the direction in which Anda Automation continues to strive.

"If you want to go fast, go alone; if you want to go far, go together." We deeply understand that every technological advancement stems from close collaboration with customers and partners. We sincerely invite you to visit our booth, experience the charm of cutting-edge technology firsthand, and join us in discussing industry trends and exploring new chapters of development together!

We look forward to welcoming you at NEPCON ASIA 2025!

Find us at Hall 13, Stand 13D70.