NEPCON ASIA 2025 Concludes Successfully in Shenzhen

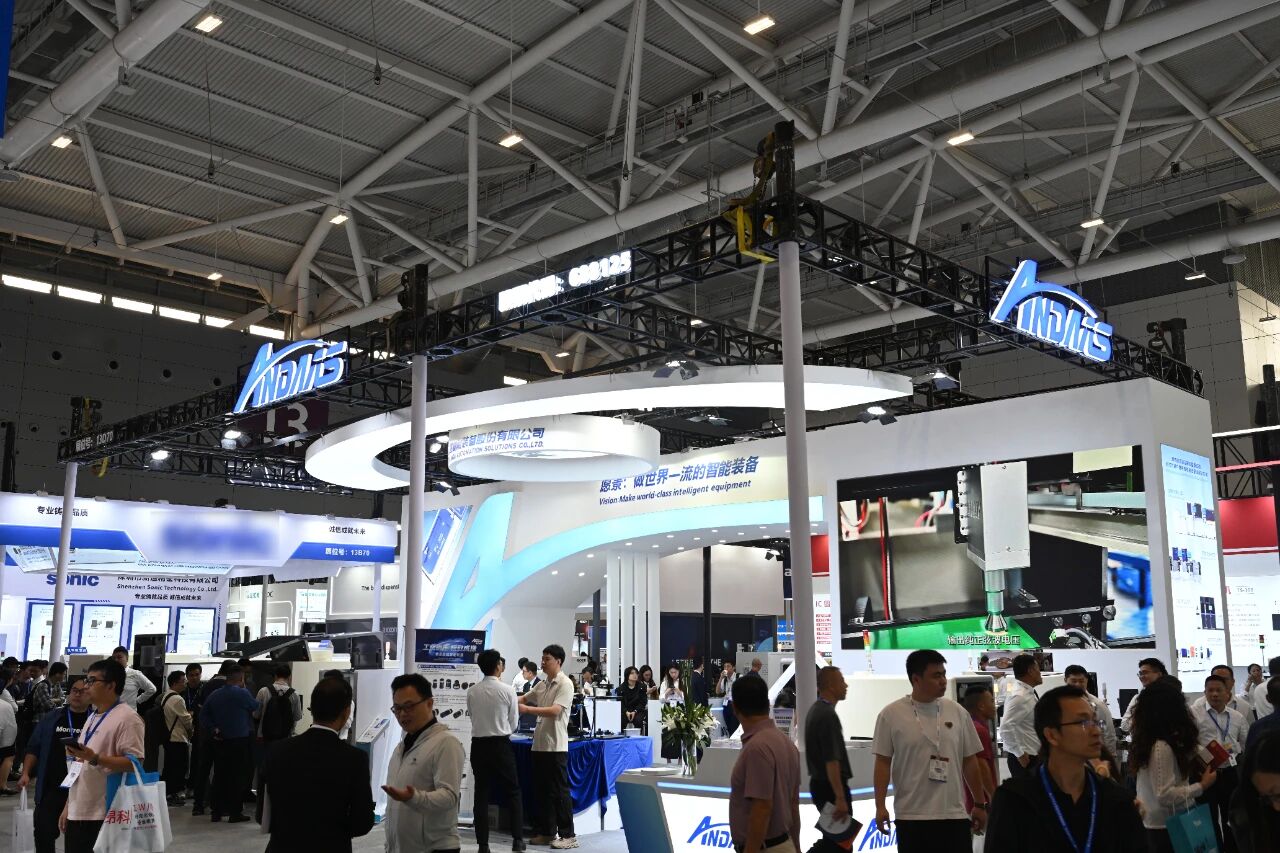

The three-day NEPCON ASIA (Asian Electronic Production Equipment and Microelectronics Industrial Exhibition) successfully concluded on October 30 at the Shenzhen World Convention & Exhibition Center. This premier industry gathering brought together global leaders and innovators in electronics manufacturing to collectively chart a clear blueprint for the "Intelligent Manufacturing Future."

At Booth 13D70 in Hall 13, Anda Automation presented a technological feast centered on the theme of "Precision Empowerment," showcasing integrated solutions spanning precision processes, intelligent inspection, and the digital future. The demonstration garnered extensive attention and deep recognition from industry peers.

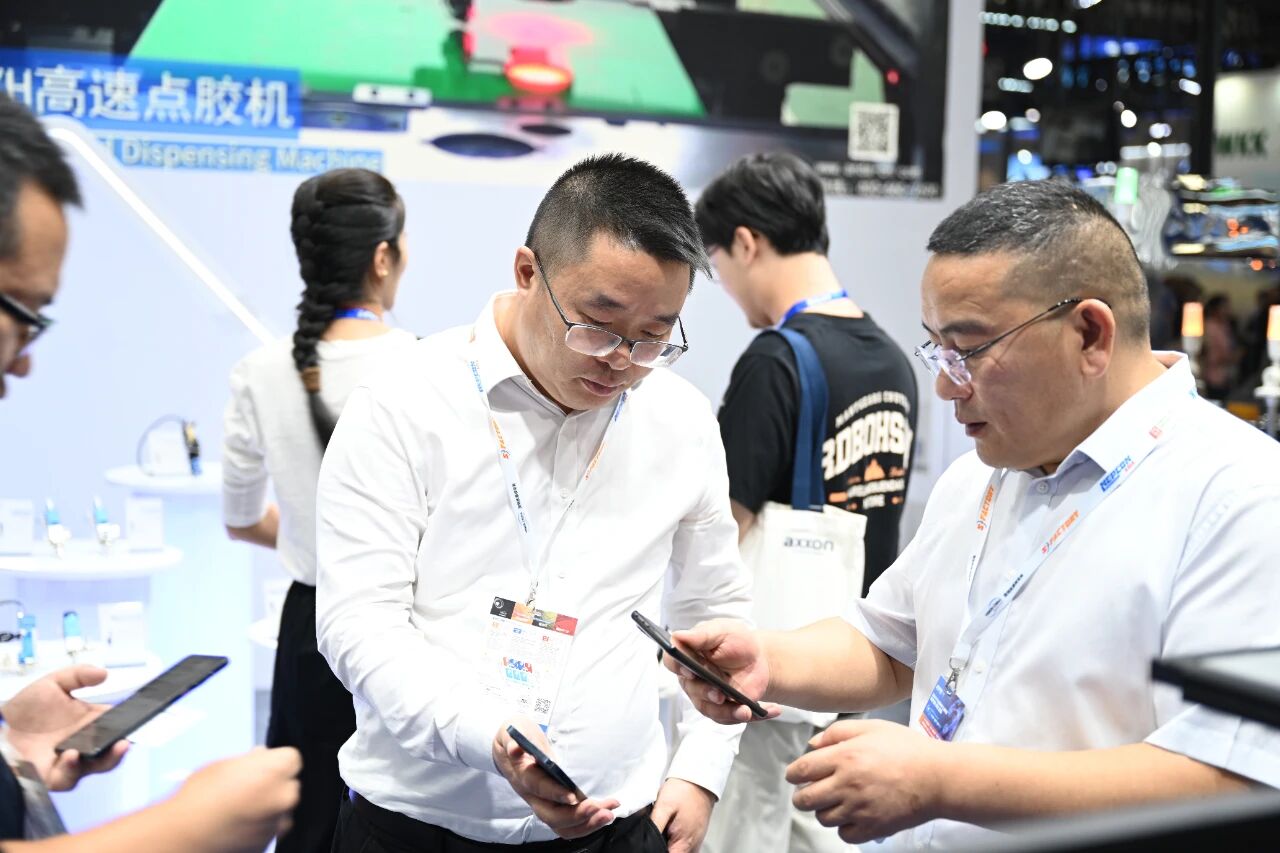

During the exhibition, the Shenzhen World Convention & Exhibition Center was buzzing with activity. The lively exchanges between professional visitors and exhibitors fully demonstrated the vitality and promising future of the electronics manufacturing industry.

The Anda Automation booth consistently attracted significant attention, and we were genuinely impressed by the strong interest and immediate needs expressed by our partners, both existing and new, for our integrated automation solutions.

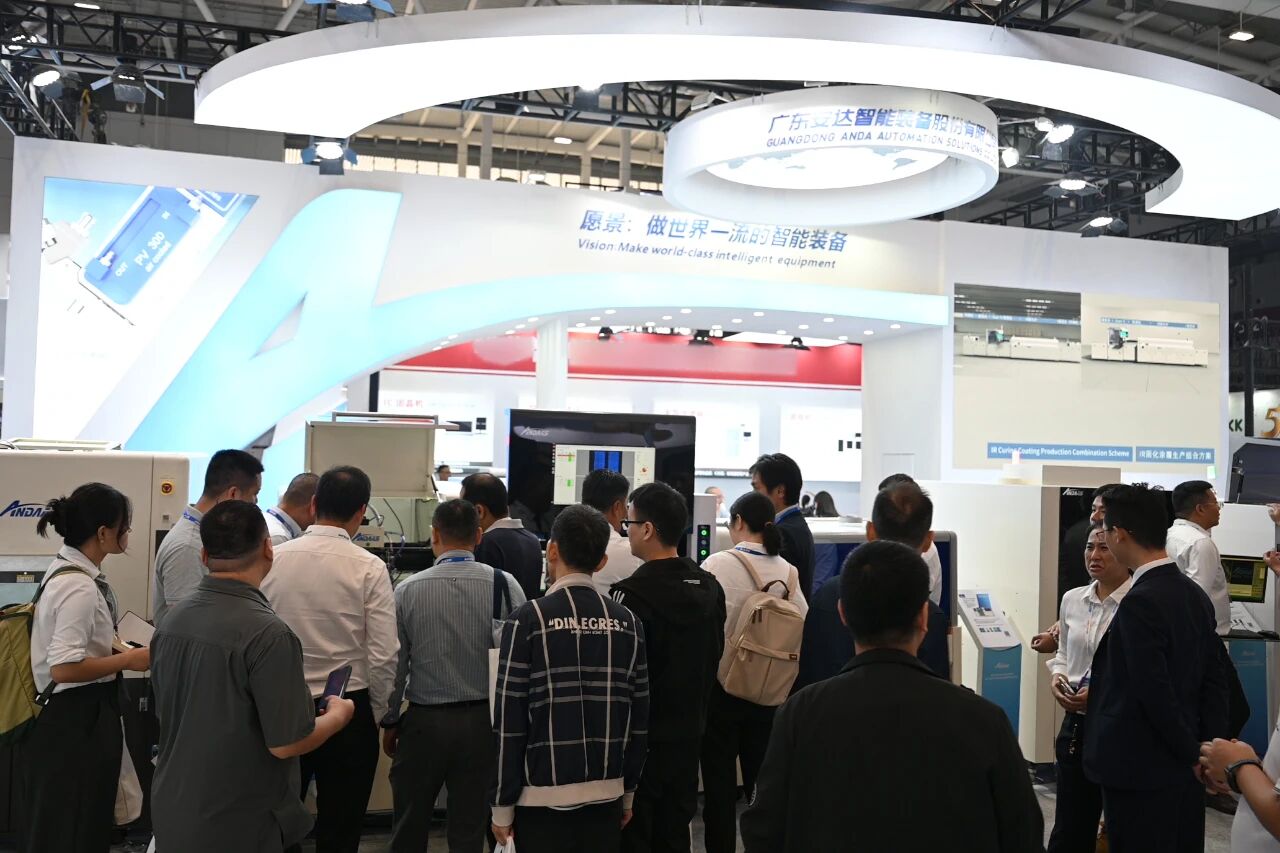

Live Demos: Showcasing the Future of Intelligent Production

For this exhibition, we moved beyond static displays to transform our entire booth into a compact "smart production line." This approach brought all equipment to life, making our technological advantages truly visible.

New Product Demos: Highlighting Cutting-Edge Technology

The joint demonstration zone for our new-generation AOI system and digital spraying solution attracted significant attention. While no physical workpieces were processed, the AOI system, through its dynamic operational demo, clearly showcased its high-speed scanning capabilities and the strong potential of its deep learning algorithms in simulating defect recognition. Nearby, the spraying robot executed precise轨迹模拟空跑, accurately simulating its movement path over complex 3D surfaces. Supported by video presentations, it detailed the innovative principle of adhesive jet 3D printing, which builds forms layer by layer without the need for fixtures. This dynamic demonstration vividly outlined the clear contours of future intelligent production for our visitors.

Proven Fluid Control Equipment: Demonstrating Reliable Performance

In the mature process demonstration zone, our equipment, while not processing physical workpieces, proved its exceptional reliability through continuous and stable no-load operation. The high-precision dispensing system and fully automatic coating machine accurately replicated pre-set complex trajectories. The plasma cleaning system, through its supporting demonstration device, visually compared the significant change in water contact angle on material surfaces before and after activation. Meanwhile, the two-component automatic potting system fully demonstrated its internal processes of vacuum degassing and ratio control. The stable, dynamic operation of these units served as powerful testimony to the robust quality and reliability of Anda Automation's products.

Static Display of Core Components: Analyzing the Technical Foundation

We specifically designed a static display zone for core components, presenting these fundamental "building blocks" – such as high-performance optical lenses and precision valves – directly to our audience. This area attracted numerous seasoned engineers who examined them closely. Through the physical components and on-site technical explanations from our engineers, they gained deep insights into how these core parts ensure the equipment's performance at a fundamental level, providing valuable references for their own equipment selection and technical upgrades.

To help our audience gain a deeper understanding of the core technologies, we specially organized multiple "Product Technical Briefing Sessions." These sessions featured focused, professional explanations centered on the iPjet-7 Digital Spraying System and the Fly-Vision AOI inspection system.

During the iPjet-7 digital spraying session, the presenter systematically explained how the equipment achieves precise, micrometer-level control of adhesive dispensing through non-contact jetting technology—perfectly avoiding non-target areas and significantly improving edge definition. By accurately controlling coating thickness and leveraging its path-planning capabilities, it enables an innovative photosensitive material coating process based on UV adhesive 3D printing, tripling the application efficiency. The iPjet-7 is particularly suited for precision coating and encapsulation protection in fields such as new energy vehicle electronics and 3C products.

The Fly-Vision AOI session focused on its core advantage of "on-the-fly inspection." The presenter detailed how the system performs positioning, inspection, and judgment simultaneously during high-speed movement via real-time image capture and AI algorithm analysis, significantly reducing cycle time and boosting overall production line efficiency. Through vivid case studies and parameter comparisons, the audience gained an intuitive understanding of the Fly-Vision AOI's value in enhancing flexible manufacturing capabilities.

Each session drew large crowds of professional attendees who listened attentively. The Q&A segments featured spirited discussions, with numerous clients engaging in in-depth exchanges with our technical team regarding specific application scenarios within their production lines.

A Hub of Deep Technical Exchange: Solving Challenges Together

Another major highlight was our dedicated zone for in-depth technical dialogue, where our senior engineers engaged directly with visitors. Throughout the three-day event, this area remained the most vibrant hub for intellectual exchange. Our engineering team held intensive one-on-one discussions with hundreds of technical professionals from sectors including consumer electronics, semiconductors, new energy vehicles, and medical devices.

We observed that many clients arrived with clearly defined objectives, deliberately bringing their product samples and specific process challenges—from troublesome stringing during dispensing, to uniformity issues on complex curved surfaces, and the need for quantifiable adhesion improvement after plasma cleaning. For each case, our engineers provided detailed preliminary analysis based on substantial field experience and proposed actionable solution pathways.

While many in-depth process validations couldn't be completed in the bustling exhibition environment, the consensus reached on site led to scheduled follow-ups for deeper discussions and validation plans. This practical, results-oriented communication efficiently translated our promise of "helping you open a new chapter in intelligent manufacturing" into concrete action.

Aligning with Industry Trends: The Integrated Solution Advantage

Through exchanges with numerous industry leaders, we clearly sensed the unstoppable momentum toward intelligent and flexible manufacturing. While individual equipment upgrades remain important, companies increasingly seek integrated, turnkey solutions that combine pre-treatment, precision processing, in-line inspection, and data traceability. This is precisely where Anda Automation continues to advance and what we comprehensively demonstrated at the exhibition.

Our display of the complete process chain—from plasma surface treatment, to precision dispensing/coating/potting, and through to AOI intelligent inspection—directly addresses this industry evolution.

The exhibition has concluded, but the journey of thinking and exploration continues. We return with invaluable client feedback, cutting-edge industry insights, and promising collaboration prospects.

Our sincere gratitude to every visitor of the Anda Automation booth—your attention and wisdom give our technology greater value. We also extend our thanks to the organizing committee, all our partners, and every dedicated team member for their hard work.

On this journey to an intelligent manufacturing future, Anda Automation looks forward to continuing forward with you. Building on what we gained at this exhibition, we will deepen our expertise and continuously evolve our technologies and solutions. We anticipate our next meeting, where we hope to unlock new possibilities together!