In the electronics manufacturing industry, PCB coating processes have long faced numerous challenges: varying component heights, hard-to-reach areas, diverse types of adhesives, and the difficulty of balancing precision with consistency... Are these also the challenges your production line is encountering?

Anda Intelligent’s iCoat series of precision coating machines is a high-performance coating solution developed to address these industry pain points, helping enterprises achieve high-quality, high-efficiency, and highly consistent coating processes.

The iCoat series offers three models, precisely tailored for diverse scenarios.

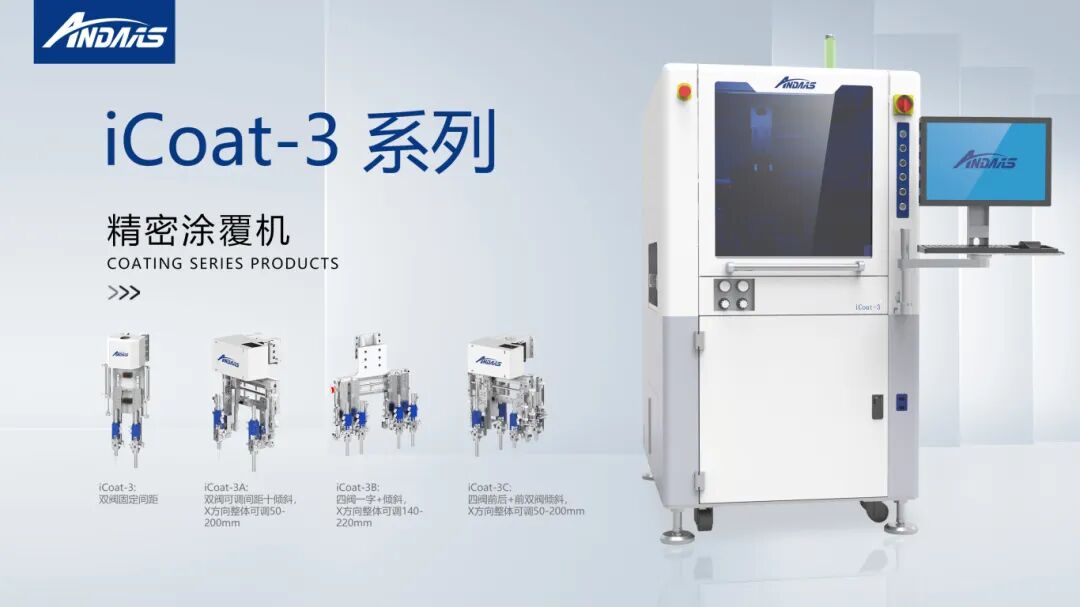

iCoat-3: Expert in High-Efficiency Large-Area Coating

lIdeal for selective coating over large areas with multi-panel boards, high throughput requirements, and diverse processes;

lSupports flexible configuration and arrangement of multiple valve types, easily adapting to complex panel production;

lBuilt-in spray effect detection function enables real-time quality control, significantly improving mass production consistency.

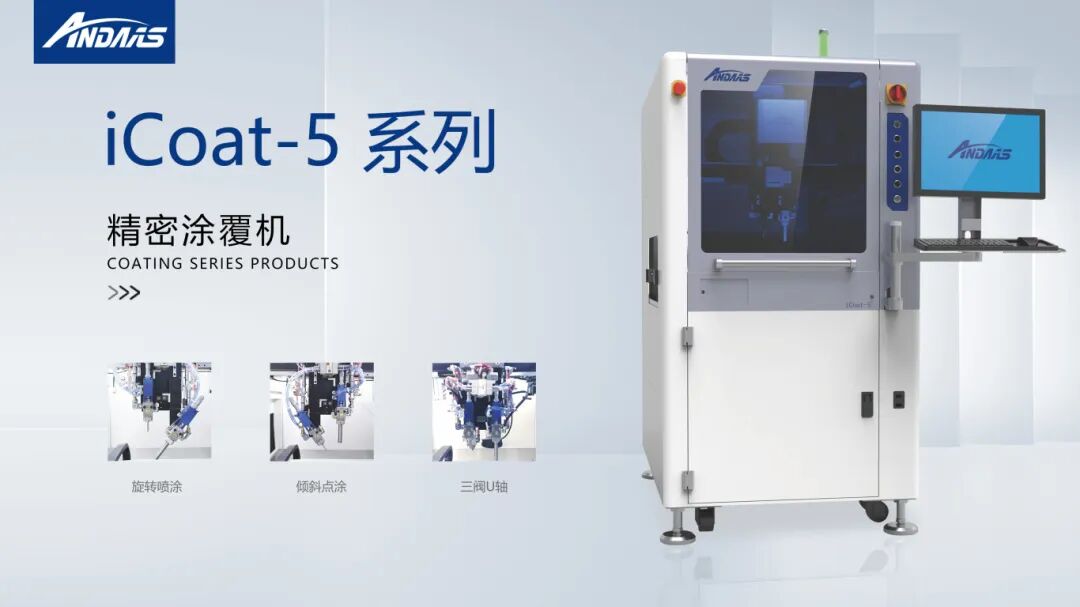

iCoat-5: Pioneer in Multi-Angle High-Precision Spraying

lBreaks through the bottlenecks of coating tall components and multiple hard-to-reach areas, achieving omnidirectional coverage;

lServo motor + imported ball screw module ensures high-speed, high-precision operation with excellent stability;

lParticularly suitable for products with varying component heights and complex structures, offering far superior coating uniformity compared to similar equipment.

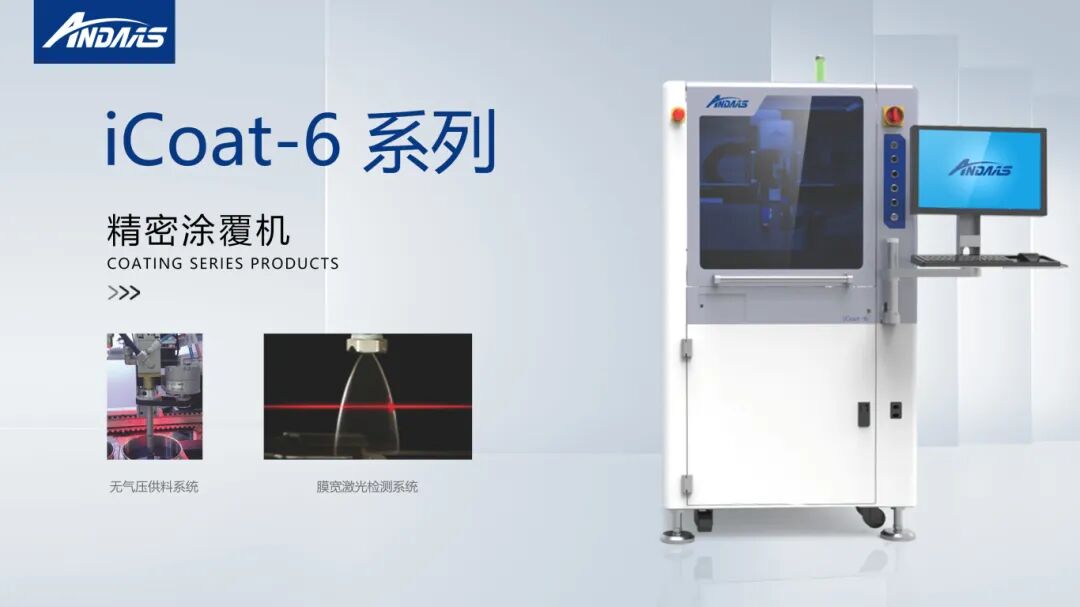

iCoat-6: Flagship for High-Definition Edge Film Coating

lEquipped with a dedicated film valve for high-precision edge control without jagged edges or splashing;

lIntegrated pressure-free feeding + fluid heating circulation system ensures stable viscosity and minimal bubbles, with material utilization rates as high as 99%;

lSupports laser detection of film width + fiber optic liquid level sensing, offering high intelligence and low maintenance costs.

Why has the iCoat series emerged as the leading choice in the intelligent equipment industry?

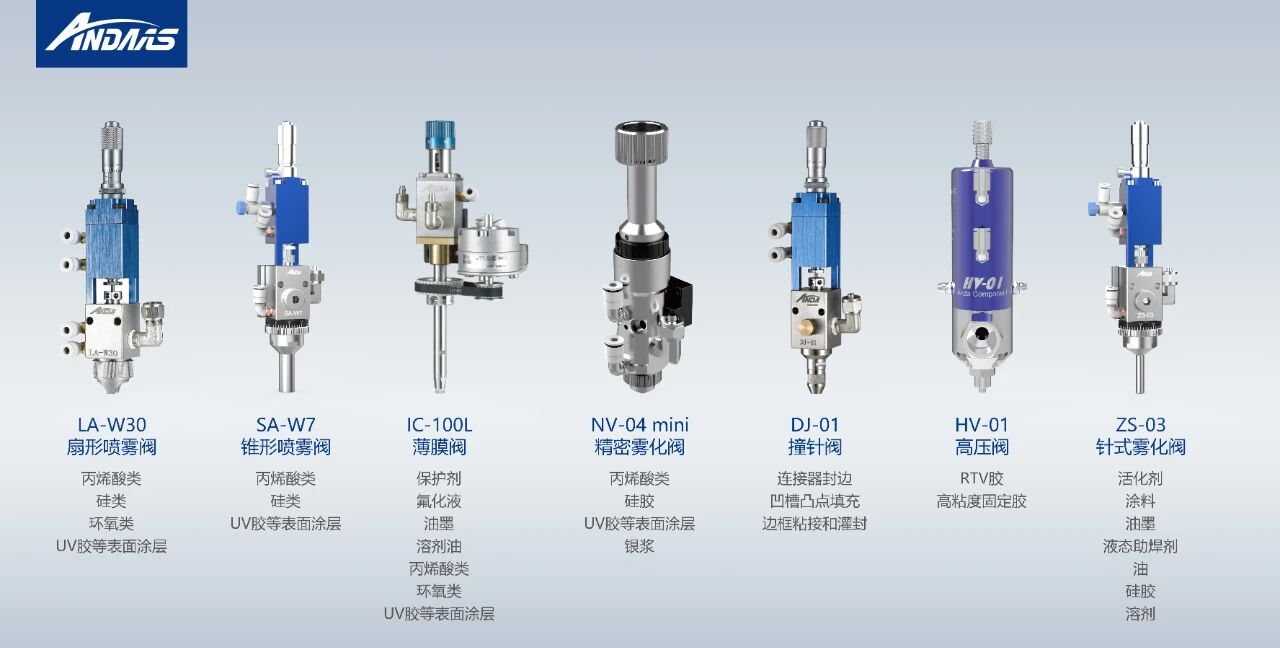

l One Machine, Multiple Valves, Strong Compatibility: Supports seven valve types including needle atomizing valve, fan valve, conical valve, high-pressure valve, needle valve, and film valve, covering a viscosity range of 0–3500 CPS.

l Real-Time Detection, Visual Quality Control: The entire series features spray effect detection functionality, supports manual real-time monitoring, and includes barcode recognition for error prevention.

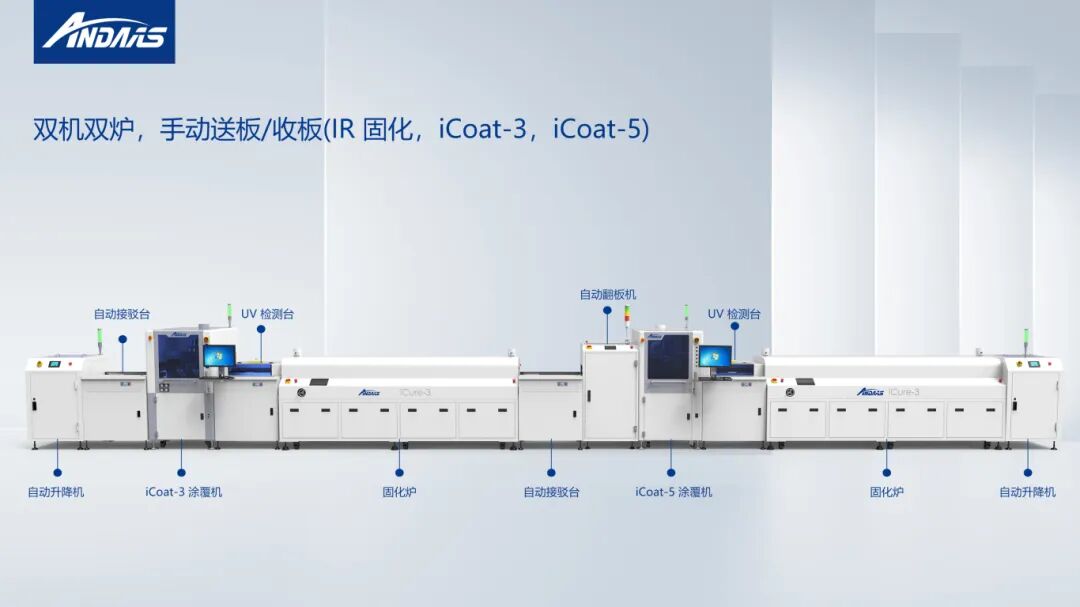

l Smart Connectivity, Full-Factory Solutions: Supports flexible production line configurations from "Single Machine Single Oven" to "Dual Machine Dual Oven," seamlessly integrating UV inspection and curing processes.

Seamless full-line integration and one-stop solutions.

Anda Intelligent provides various full-line solutions such as Dual Machine Dual Oven and Single Machine Single Oven, integrating multiple processes including coating, UV inspection, and curing to achieve end-to-end automation, significantly enhancing overall line efficiency and consistency.

Whether for consumer electronics, automotive electronics, or medical PCB manufacturing, Anda Intelligent's iCoat series delivers reliable and efficient coating assurance.