On the afternoon of September 29, ANDA Intelligent successfully hosted the new product launch event titled "Intelligent Coating & Inspection, Crafting Excellence – Our Next-Gen Manufacturing Engine" at its headquarters. The event marked the official launch of the iPJet-7 digital spraying machine, which is based on 3D printing technology, representing a critical step forward in the fields of intelligent manufacturing and digital encapsulation.

The New Era of Digital Spraying Has Begun

At the beginning of the launch event, Mr. Xia Xumin, Deputy Director of the R&D Center, delivered the opening speech. He stated, "The iPJet-7 is not merely a piece of equipment; it represents a crucial step for ANDA Intelligent's transition from 'manufacturing' to 'intelligent manufacturing'. By deeply integrating our years of expertise in fluid control technology with 3D printing, machine vision, and digital modeling, it redefines the process standards for surface encapsulation." His speech provided a visionary perspective, establishing a tone that emphasized both technological advancement and innovation for the launch event.

What are "Intelligent Coating" and "Intelligent Inspection"?

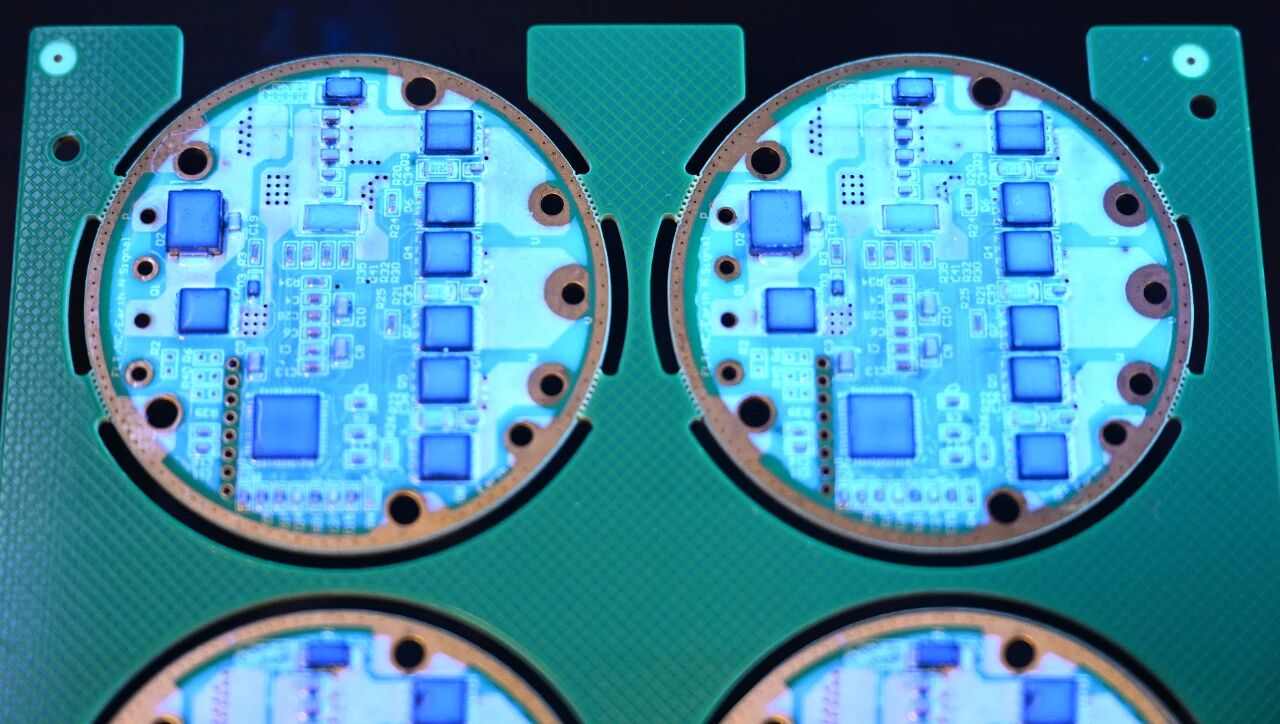

"Intelligent Coating" refers to the high-precision digital printing technology adopted by the iPJet-7. Utilizing thousands of independently controlled piezoelectric nozzles, it jets UV resin onto the surfaces of electronic components such as PCBs and FPCs with micron-level accuracy, achieving a 3D, "armor-like" protective encapsulation.

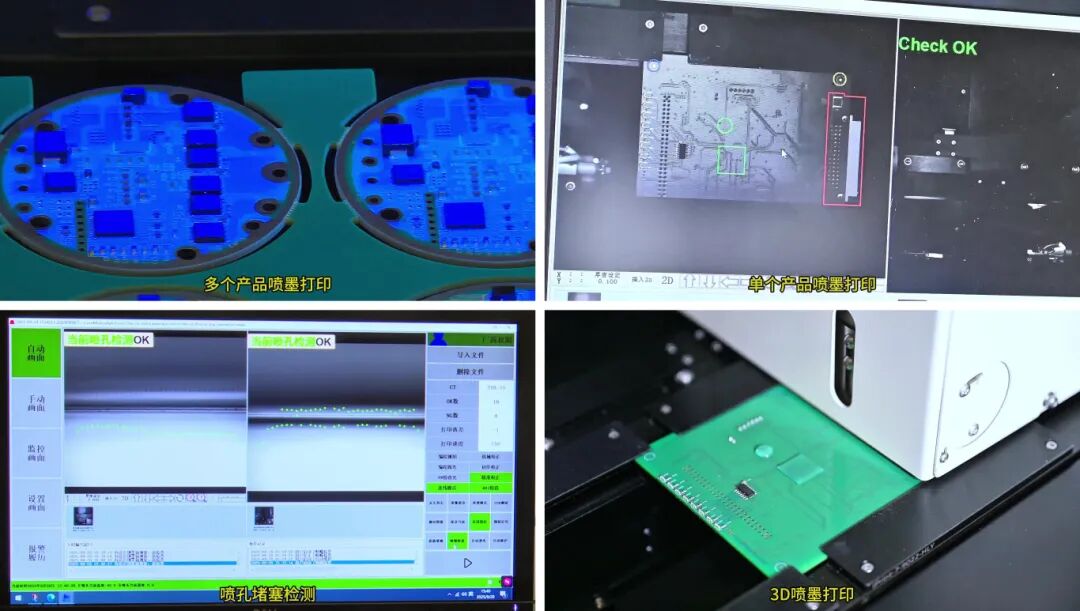

"Intelligent Inspection" is embodied in its suite of smart features, including the intelligent vision system, vision-guided alignment, nozzle self-checking, AOI (Automated Optical Inspection) for quality control, and automatic moisture maintenance. These functions collectively ensure stable, reliable, and zero-defect operation even at high production speeds.

Key Innovations: Beyond "Spraying", It's "Digital Modeling"

Fully Digital Process Workflow: Supports the import of multiple file formats (Gerber, CAD, STL, PDF), realizing the concept of "What You Design Is What You Produce".

Intelligent Printhead System: Features over 1000 independently controlled nozzles, with a resolution of 400 dpi and a minimum droplet volume of 80 pl.

3D Stacked Encapsulation: Utilizes UV-LED water-cooled curing for layer-by-layer stacking, achieving a single layer thickness as fine as 0.016mm for precise height control.

Zero Manual Intervention Maintenance: Integrates smart maintenance functions including automatic moisturizing, nozzle clog detection, and adhesive circulation.

Eco-Friendly & Energy Efficient: Solvent-free operation, generates no wastewater, and improves material utilization by at least one-third.

Live Q&A: Focusing on Value, Addressing Queries

Following the engaging presentation session, the event transitioned into a lively Q&A segment with an enthusiastic atmosphere. Multiple colleagues actively raised questions, engaging in in-depth discussions with Mr. Xia and the technical team regarding the product's practical applications, technical specifics, and market potential.

How is the iPJet-7 different compared to conventional dispensing/coating machines?

Value Propositions for Our Customers

Enhanced Yield Rate: Precision spraying prevents overflow and splashing, thereby enhancing product reliability.

Cost Reduction & Efficiency Improvement: Simplifies process flows, saving on labor, material, and time costs.

Flexible Production: Supports quick changeovers for small-batch, high-variety production, adapting to the high-frequency line change requirements in electronics manufacturing.

Green Manufacturing: No harmful volatiles, aligning with environmental protection and occupational health standards.

Market Prospect: Digital Packaging is Right on Time

The rapid development of high-end electronics such as 5G, new energy vehicles, semiconductors, and Mini/Micro LED has placed higher demands on PCB protection processes—requiring greater precision, reliability, and flexibility.

The launch of the iPJet-7 represents a significant step by ANDA Intelligent to respond to these market trends and lead the "intelligent manufacturing upgrade." We believe that this spraying equipment, which integrates digital modeling, 3D printing, AI vision, and intelligent operation and maintenance, will become ANDA Intelligent's new standard platform in the field of electronic encapsulation.

Smart Coating, Smart Inspection: Forging Mastery

At the launch event, we not only unveiled the product and provided in-depth explanations but also set up a physical exhibition and interactive experience zone. This allowed attending colleagues to witness firsthand the capabilities of "Intelligent Coating" and "Intelligent Inspection" with the iPJet-7.

ANDA Intelligent remains committed to driving the upgrade of the intelligent manufacturing industry and becoming a world-class provider of smart equipment.

The iPJet-7 is more than just a machine—it is the inception of the next-generation manufacturing engine.