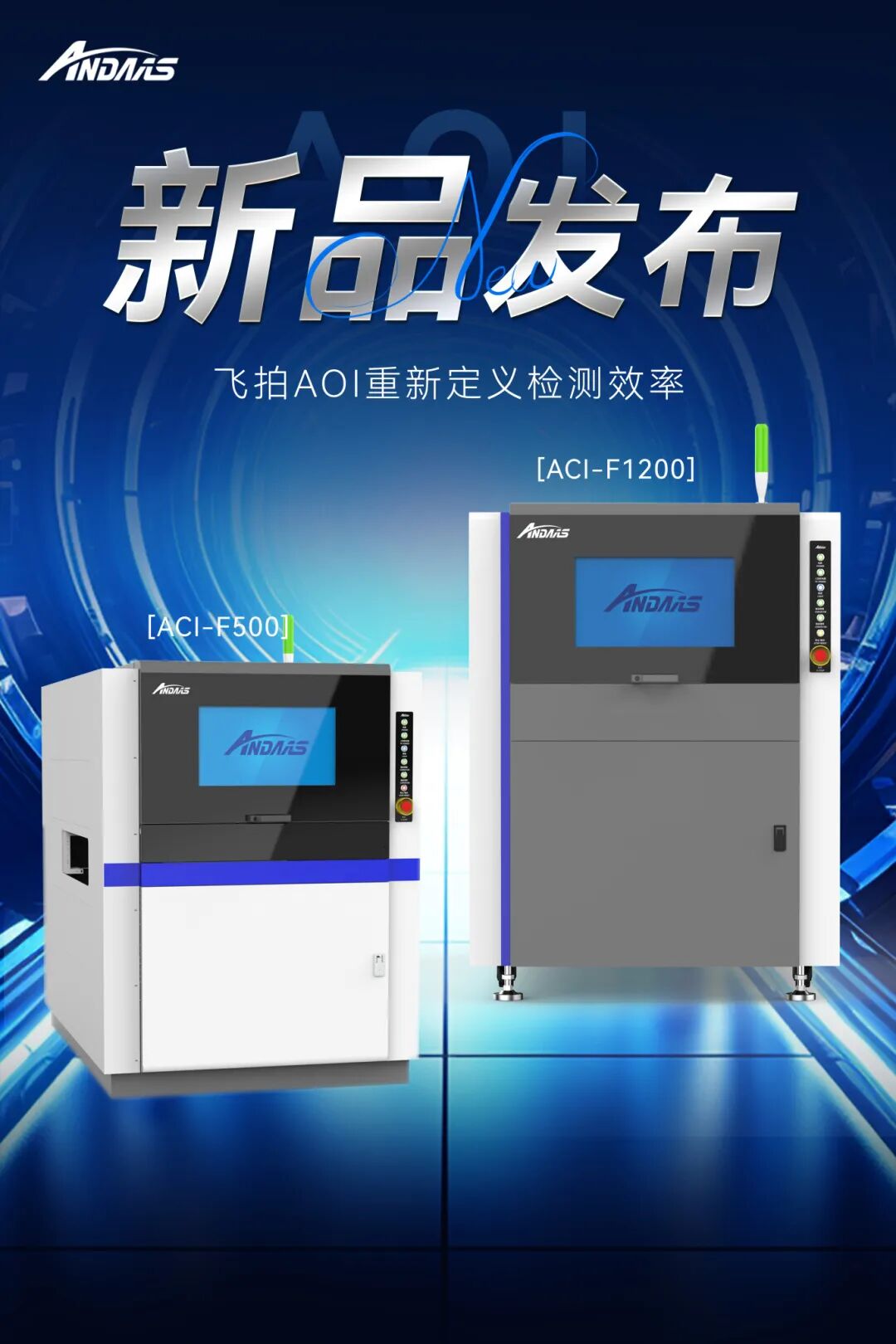

On October 22, Anda Automation grandly held the new product launch event themed "Fly-Vision World, Precision Future," officially unveiling the world-leading intelligent inspection equipment—the Double-Sided Fly-Vision Coating AOI equipment ACI-F1200/ACI-F500 series.

A groundbreaking achievement in the company's portfolio of vision inspection solutions, this equipment deeply integrates fly-vision technology with AI visual algorithms, redefining the benchmarks for efficiency and accuracy in industrial inspection. It empowers sectors such as electronics manufacturing, automotive, medical, and home appliances to step into an efficient, precise, and intelligent future.

At the launch event, General Manager Wang delivered the opening speech. Subsequently, Dr. Wan Junshe, the head of the AOI team, took the stage for the product launch presentation. He provided an in-depth interpretation of the robust capabilities of the Double-Sided Fly-Vision AOI, elaborating on its technical architecture, application scenarios, and real-world performance data.

1、Dual-sided flying photography coating AOI:Redefining Coating Inspection with an Efficiency Powerhouse

Amid the wave of intelligent manufacturing, precision inspection of the coating process is critical for ensuring product quality. Traditional AOI equipment is often constrained by low inspection efficiency, poor compatibility, and operational complexity. The advent of Double-Sided Fly-Vision AOI shatters these technological barriers, leading industry innovation with four core advantages:

The ACI series is equipped with Anda Automation's self-developed Fly-Vision system, enabling high-resolution image capture while in motion. Compared to traditional static imaging, inspection efficiency is increased by 50%, with a simpler structure and more stable operation. Paired with a proprietary anti-shake algorithm, it ensures clear and stable images even at high speeds, truly achieving "dynamic capture, static precision."

The deep learning AI algorithm, based on PyTorch and TensorRT, supports intelligent recognition across all scenarios—from zero-defect to multi-defect samples. The proprietary ACC-Unet algorithm improves defect analysis efficiency by 30% and delivers a detection accuracy of up to 99.9%, easily handling complex defects such as over-glue, under-glue, splashing, bubbles, and foreign objects.

The equipment supports new product programming within 30 minutes and production line optimization in 60 minutes. Its modular optical system allows for rapid replacement. Coupled with a "codeless" graphical interface, inspection processes can be configured without programming, significantly reducing the learning curve and deployment time.

The innovative dual-sided synchronous inspection technology completes both-side inspection in a single pass, doubling production capacity. Combined with a high-precision positioning system, the ACI-F1200 achieves a pixel accuracy of 15μm and a detection accuracy of 75μm, while the ACI-F500 reaches a pixel accuracy of 21μm and a detection accuracy of 100μm, meeting the demands of various precision scenarios.

2、Core Specifications: Engineered for Efficient Inspection

As an industrial-grade, high-precision inspection system, the Double-Sided Fly-Vision AOI demonstrates its robust capabilities through its technical specifications.

Inspection Speed: Achieves 50% higher efficiency in Fly-Vision mode, supporting high-speed continuous production.

Precision & Stability: Maintains an overkill rate of <0.5% and an escape rate of <0.1%, with positioning accuracy within ±0.02mm.

Adaptability: Supports a maximum working area of X680mm × Y620mm, compatible with a wide range of product sizes.

Reliability: Operates on 220V power with servo drive and requires an air pressure of ≥0.7±0.05MPa, ensuring 24/7 stable performance.

With its high efficiency and precision, the Dual-sided flying photography coating AOI is widely applied across multiple sectors:

Electronics Manufacturing: Inspecting PCB coating to enhance product reliability.

Automotive Industry: Ensuring the quality of battery gel encapsulation in new energy vehicles for safety performance.

Medical Devices: Detecting coating uniformity on precision instruments to meet stringent sterilization requirements.

The launch of the Dual-sided flying photography coating AOI is another powerful embodiment of Anda Automation's commitment to "Intelligent Manufacturing in China." Moving forward, we will continue to leverage technological innovation as our driving force, empowering the global manufacturing industry to step into a more efficient, precise, and intelligent era.